FAQ

VirtualDieCasting is a web portal owned by TF s.a.s. that deals with mechanical design in the world of molds in Villa Carcina (Brescia).

Our job is to design components and molds and to make filling analysis to obtain the maximum quality of the diecasting part.

We have 4 workstations with a total of 50+ cores available to calculate your filling and solidification processes.

We use simulation software that has the particularity of being bi-phasic, that is to simulate both air and metal in every cell of the mesh. During filling only the relative percentage changes but both will always be present. This allows us to be particularly precise in predicting the distribution of trapped air at the end of filling.

The result of our work is one or more reports.

A report will be produced for each analysis requested

Look down to:

- Help Report Solid

- Help Report matching

- Help Report filling

Analytical moldable analysis.

Calculation of the theoretical and optimized values taking into account the dynamic performance of the machine, the geometries and the casting requirements, providing an excellent starting point from which to set the parameters in production.

The output is expressed in common language and indicates which problems have been encountered and what corrections can be made to solve them. Production of the PQ2 diagram and simulation of the influence of working conditions on the process, such as, for example, particularly low mold temperatures or simulating the effect of a variation in the number of figures.

Full casting simulation with biphasic die casting simulator.

Metal and air are modeled simultaneously from a mathematical and fluid-dynamic point of view. This feature allows extreme accuracy in the simulation of the filling, including metal pulverization phenomena and movement of air inclusions, allows the correct analysis of vacuum casting, calculation of air speeds and validation of air vents. Parallel to this, analysis and visualization of the filling through animation and images of the distribution of the main variables (speed, temperatures, pressures, etc.) are also available, highlighting the areas where it is possible to have critical speeds, the filling path, the cold points and the cold junctions, the areas where there is the incorporation of air. This information allows to optimize the geometry of the branch and of the casting connections, the position of the overflows and of any air vents or of the vacuum circuits.

At the end the simulation is completed with the simulation of the solidification with virtual mold and heat map deriving from the filling, taking into account the thermophysical properties of the alloy depending on the temperature. Display of solidification times and shrinkage porosities expected.

Simulation of the solidification with virtual mold with uniform temperature equal to that set, taking into account the thermophysical properties of the alloy depending on the temperature.

Display of solidification times and shrinkage porosities expected.

You will have low prices because we use highly efficient machines that allow us to reduce the calculation times together with the use of standardized procedures and formats for analysis and reporting.

The thickness of the part is the most critical parameter to assign. It represents the predominant thickness and/or what we have to obtain with the set quality

VirtualDieCasting is completely Italian and all activity take place in our only Headquarters located in Italy in Villa Carcina (Bs) in via Italia 85.

FILE FORMATS

.STL – Only files with SINGLE parts are accepted, that is the whole casting

MAXIMUM NUMBER OF ELEMENTS FILE.STL: 1 MILLION ELEMENTS

WALL THICKNESS

The nominal thickness of your piece must be greater than 1mm. Pay attention to details less than 1 mm because they usually do not survive to the mesh phase.

CHARACTERS AND LOGOS

If you can, remove all the logos, brands or writings from your model. These usually do not affect the filling fluid dynamics but only complicate the mesh of the part.

If it is not possible, we will delete them and then we will ask you to confirm the operation.

FILETTATURE INTERNE ED ESTERNE

Model threads only if actually present and necessary for the geometric description of the part.

If in doubt, do not hesitate to contact us by clicking here

We accept the .stl formats

MAXIMUM NUMBER OF ELEMENTS FILE.STL: 1 MILLION ELEMENTS

The maximum size is 100Mb per single file or 1 million of elements

If you wish, you can upload the compressed file to a .ZIP file

These export format is present in almost all the most used 3D mechanical CAD: Solidworks, Rhino 3d, Creo, NX, CATIA, Autocad mechanical and many others.

Click here to upload a file for solidification without channels

Click here to upload a cavity filling file

Once the 3D geometry has been loaded and your order has been sent, we will examine it and within one working day you will receive a contact from an expert VirtualDieCasting who will confirm the correctness of the information provided or suggest any changes. So it will always be possible to submit to the VirtualDieCasting experts any questions about the diecasting process and the relationship between it and the geometry of the part, so you can make any changes that may be necessary.

Together with the technical approval of the geometry you will receive a schedule with the expected delivery of the report.

There are 2 fast solutions:

1) By clicking here you can download FreeCAD which is an excellent 3D CAD easy to use but at the same time will allow you to create a professional 3D file: it is a open souce project and it is completely free.

2) Or by clicking the links below by directly contacting the TFlab designers who will be happy to help you. Request for offer for TFLab

The alloy available are those found in the online alloy list.

If you want to be informed in real time on the characterization of new alloy, subscribe to the newsletter by entering your email address by clicking the “subscribe to the newsletter” button. In addition to information on news, you will receive offers and discount vouchers reserved for members.

If you want to use a specific alloy we can characterize it. Contact us at desk@virtualdiecasting.com providing us with the information you have about your alloy and we will tell you how we can help

The machine available for the hot and cold chambers are those found in the online molding machine list.

If you want to be informed in real time on the characterization of new machines, subscribe to the newsletter by entering your email address by clicking the “subscribe to the newsletter” button. In addition to information on news, you will receive offers and discount vouchers reserved for members.

If you want to use a specific molding machine we can characterize it. Contact us at desk@virtualdiecasting.com providing us with the information you have about the desired machine and we will tell you how we can help you.

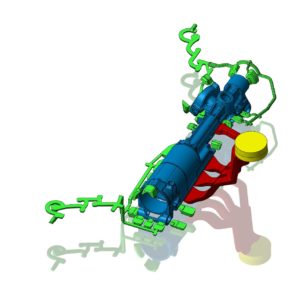

To enter the correct data it is useful to introduce a shared terminology. We indicate the colors of the parts that we must specify to fill in this section. We refer to the following image.

Biscuit: yellow

Runners: red

Casted Part: blue

Overflow: green

The subscription of a Wallet allows to have a credit towards VirtualDieCasting.com for the realization of simulations for the amount subscribed.

The Wallet is not subject to automatic renewal.

The Wallet has no time limit.

The Wallet is not refundable.

The dispatch of orders paid by Wallet and submitted by the Customer to TF s.a.s. is communicated from time to time.

By subscribing to an “All you can simulate” subscription plan you will have the opportunity to subscribe to a monthly, semi-annual or annual subscription during which you will have the opportunity to do an unlimited number of simulations.

The “All you can simulate” subscription plan is not subject to automatic renewal.

The “All you can simulate” subscription plan will end when the current term expires, unless the Customer decides to manually renew the service before that date.

The “All you can simulate” subscription plan is non-refundable.

When loading the geometry, if you do not indicate any MATCHING job, in the notes field you can specify the BASIC ESSENTIAL information to proceed:

- Alloy to be used

- Expected quality or reference sector

We also suggest indicating:

- Molding machine and/or suitable machines, if not specified we will make our proposals

- Range of possible plunger, if not specified we will make our proposals

Feel free to send an email to info@virtualdiecasting.com with all the information useful to frame the problem. We will provide you with an ad hoc quotation for your specific case.

Send an email to info@virtualdiecasting.com, we will provide you with an ad hoc quotation for your specific case.

It is quite common for companies and people who use our service to ask us to sign a Confidentiality Agreement or NDA (Non Disclosure Agreement). Companies and individuals are often suggested to use such an agreement to protect their intellectual property rights and to maintain confidentiality about their business processes.

VirtualDieCasting manages your projects with the utmost discretion, and respects the confidentiality of all information received. Our goal is to treat you as we would like to be treated.

Download the Confidentiality Agreement (NDA) model. Fill it in with your data and send it to nda@virtualdiecasting.com

- Important: all 3d files that you upload online to VirtualDieCasting.com are armored and protected with end-to-end encryption, which means that nobody can see or take possession of them.

The right to withdraw from the purchase contract refers to Italian law 22/05/1999, n. 185 “Implementation of Directive 97/7 / EC relating to the protection of consumers in respect of distance contracts” and subsequent amendments. You can consult the details on this page.

VirtualDiecasting does not send anything to the customer. It makes the Reports avaible on our TFcloud. It will be the customer’s responsibility to download the reports upon communication of their availability.

For all the details about the management of the Reports, consult the specific section in TermsAndConditions

What are the payment methods for online purchases? What is the Wallet? What is the “All you can simulate” subscription?

For all information on payments and on the case, visit our section dedicated to payments and shipments at this link