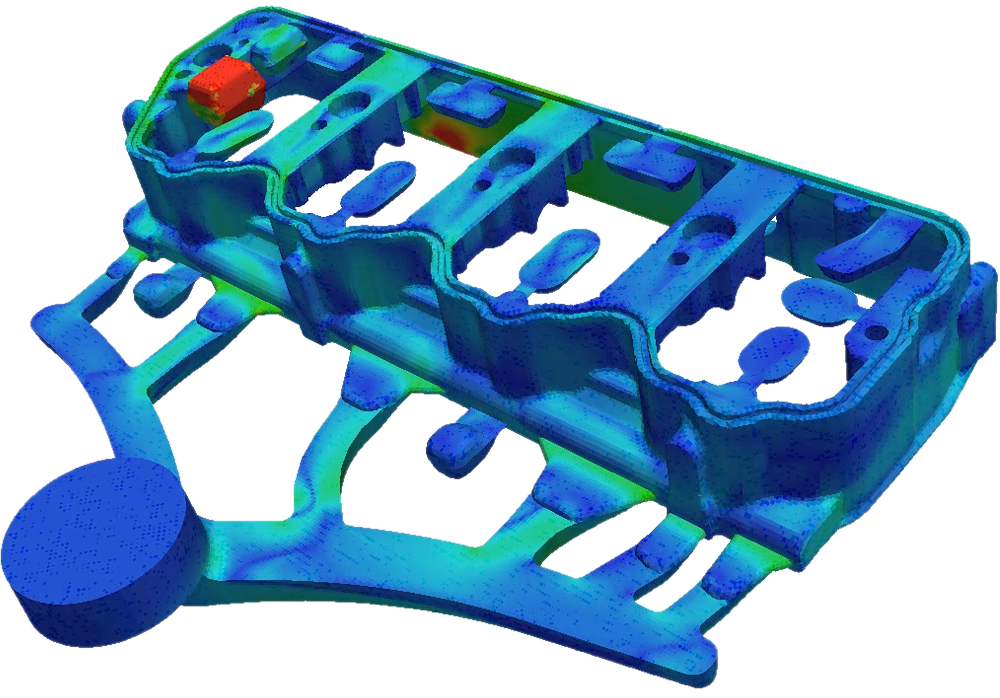

WHAT IS VIRTUAL DIE CASTING?

Virtualdiecasting.com is an on-demand service developed by TFLab for the supply of simulations and analyses concerning the filling of a mould cavity during die casting in hot chambers (hc) and cold chambers (cc).

With Virtual Die Casting you can steer the melting study in the right direction by creating a filling simulation swiftly and easily without having to purchase dedicated software or employ personnel to use the same.

Analyses reports in just 36h

The result of the Virtual Die Casting simulation is provided in a standard analysis report within 36 hours from request, containing all the data and process parameters, as well as any useful suggestions to solve any problems that may have been encountered.

PRODUCTS

LA YOUR SIMULATION IN A FEW QUICK AND EASY STEPS!

Virtual Die casting allows you to submit your simulation request quickly and easily by uploading:

Submit your request and after 36h the analysis report will be available in the download area.

If you have any special analysis requests, with a container or other specifications, send them to our team at your disposal by writing to info@virtualdiecasting.com

WHO DOES THE VIRTUAL DIE CASTING SERVICE ADDRESS

Virtual Die Casting is a web application designed for foundry engineers, designers, mould technicians and in general all those who have to produce a part using die casting processes.

The simulation request and the report received are quick and simple to carry out and understand, ensuring results within the reach of all concerned.

Our on-demand service is designed to support the operator by simulating daily activity on the press, and deliver the results of complex calculations in the most simple form possible.

ADVANTAGES

The virtual simulation of the process is a tool that enhances experience, yet does not replace it.

Carrying out multiple simulations on different mould layouts allows you to explore different alternative solutions virtually before you actually build the mould.

Choose the VDC proposal that’s right for you

With Virtual Die Casting you receive your analysis and simulation report in 36 hours, a simple and user-friendly way to assess different alternative solutions before building a mould.

View our proposals and select the licence that best suits your requirements: choose from subscriptions, wallets or single simulation.

Virtual Injection Molding is a new web application specifically developed to carry out mould cavity filling analyses starting from the 3D geometry of the part and the selected polymer.

VIM, designed for the world of thermoplastic injection moulds, allows users to carry out filling simulations of the thermoplastic injection process in complete autonomy.

CONTACT US

This contact form is dedicated to those who need prompt support on how to use the Virtual Die Casting, sales information and anyone who needs to request further technical details.

You can contact our support service at any time of the day and for any matters regarding Virtual Die Casting!